Puzzle Box Project

question

For this project, we got together in groups of 5, and we had to come up with a design for 6 sides of a box that fit together like a puzzle without using any glue and each side fit the overall theme.

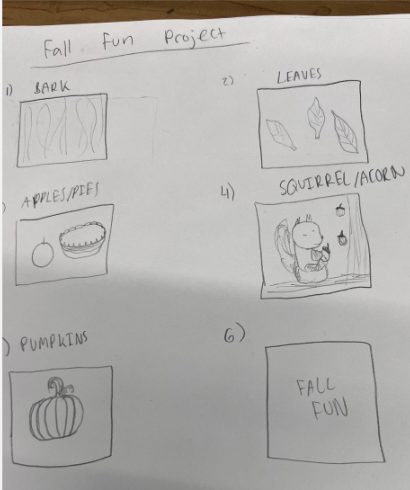

brainstorm

My group included me, Sophia, Bella, Kevin, and Liav. First, we decided since summer just ended, we decided to do a fall-themed box. Each person would get one side to design and would have to make sure their side would fit with the surrounding sides.

We made a plan of how to incorporate various fall elements into each side, such as pumpkins, apples and pies, tree bark, leaves, and squirrels with acorns. For the design details:

- The bark texture will be zoomed in to show its intricate patterns.

- The leaves will be zoomed out enough to capture the texture while maintaining the focus.

- The squirrel will be depicted in a zoomed-out view to give a broader perspective.

- The pumpkin and apples/pies will also be zoomed out to highlight their overall shape and form.

- For the "Fall Fun" side, we are still finalizing the details, but it will be presented in a zoomed-out style to fit the overall aesthetic.

plan & Design

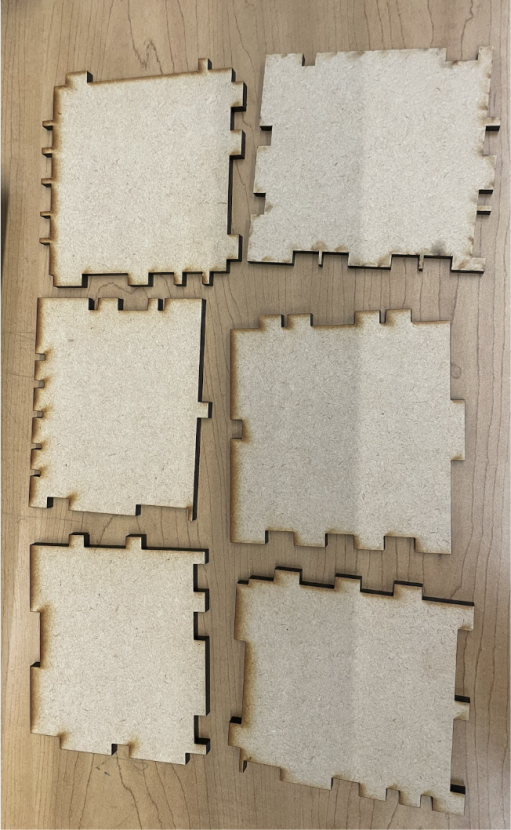

First, our main priority was to try to get the outlines of the sides to make sure our joins fit before we printed them with our designs. We first made all our joins, and we also made our designs for each side in a 4" x 4" square so that we could easily put it onto our fitting sides with the correct joins.

prototyping

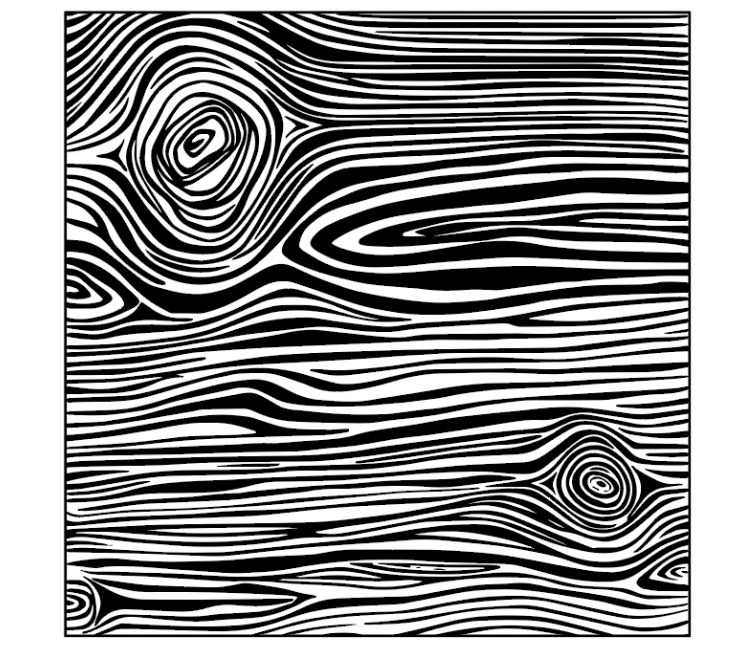

I had to create the side with the tree bark zoomed in so that when the print was executed you could feel the tree bark as if you are outside in a forest, emphasizing that fall theme we wanted to convey. I looked at images on the internet and found a good image to raster into what you see below as my CAD of the tree bark.

iteration

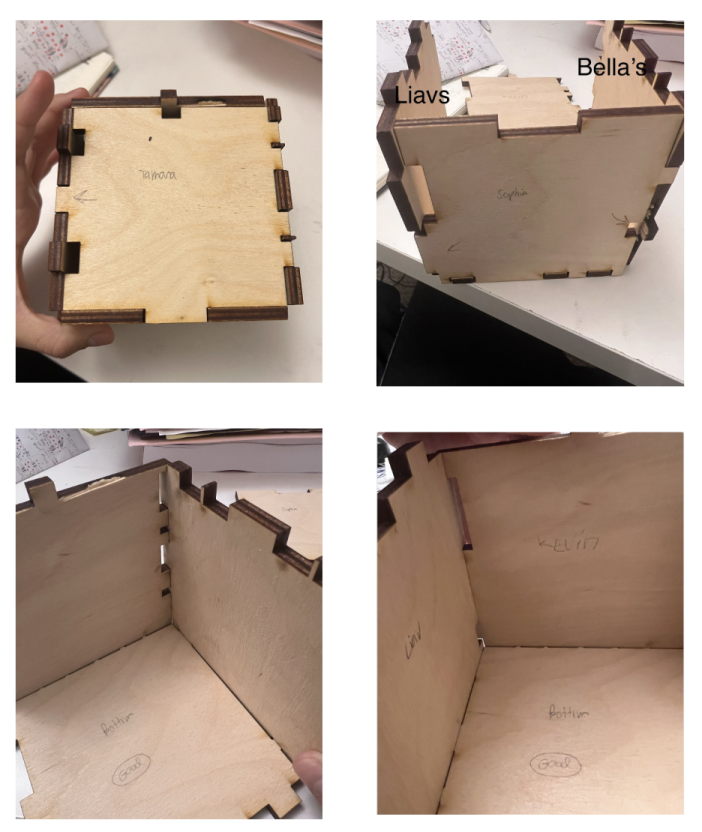

We had many iterations for this project because it was very difficult to make the joins all properly fit together. We had to constantly redesign our CADs during this process and conceptually understand how each join with interact with the others. We didn't understand how to apply 2D designs into 3D designs, which was a big issue, carrying out throughout the entirety of the project. This issue forced us to reevaluate our approach multiple times, but ultimately, it helped us learn more about the complexities of 3D design.

test cut #1

test cut #2

final cut

test & analyze

When we printed our first test cut pieces, we found many mistakes. The bottom side was the only one that fit to all sides perfectly and had no issues. However, all the other sides had at least one join that didn't fit because it was either too small or too big. There was also one tab that was sticking out that wasn't supposed too. Seeing all these issues, we went back to Adobe Illustrator and reprinted our test cuts a second time. With the second text cut, we ran into a few problems again. There was one tab that was too big for the hole. We then went back in adobe illustrator and tried to fix this problem. With our final cut, we finally printed with our designs on it, and while it was a little loose in some areas, it did all fit together, so we could successfully put the box together.

final product

Our final product did not turn out exactly as we originally envisioned, and the project ended up being far more challenging than we initially expected. We encountered several issues throughout the process, especially during the test cuts, where many of the tabs and joints either failed to fit or were slightly too large or too small, making the assembly difficult. Through these challenges, we realized that clear and consistent communication was a key factor in getting the project to work, and working together helped us problem-solve and move forward. Overall, the experience was a valuable learning process, and next time we would focus more on refining our designs and considering all possible outcomes earlier, but we are still proud of what we accomplished as a team.